Requête

Lorsque nous recevrons votre demande, nous vous enverrons par courrier électronique dans les 24 heures les catalogues personnalisés, les tables de prix,

les conditions de livraison, les conditions de paiement et les autres informations nécessaires.

coal crusher contienen

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 1. Jaw crusher. The jaw crushers are popular primary crushers for coal. They are often used in mines and quarries where large amounts of coal are mined. The working principle of the jaw crusher is to use compression force to compress coal

Consulter un spécialiste

Energy Evolution and Coal Crushing Mechanisms Involved in Coal

2023年12月16日 Chaolin Zhang, Peizhong Wang, Xianfeng Liu, Enyuan Wang, Qiaozhen Jiang Mingliang Liu. 229 Accesses. Explore all metrics. Abstract. Coal and gas

Consulter un spécialiste

Optimization of particle size distribution in circulating fluidized ...

2019年6月15日 Properties of coal gangue feed, especially its particle size distribution (PSD) and variable hardness, result in considerable impacts on both the efficiencies of

Consulter un spécialiste

煤炭破碎机_百度百科

中文名. 煤炭破碎机. 外文名. Coal crusher. 别 名. 双级破碎机. 功 能. 主要是针对高水份含量的煤炭难破碎的难题. 用 途. 一般用作粉碎煤矸石往煤里参,或者粉碎煤炭做生活之用. 目录. 1 产品特点. 2 产品用途. 3 工作原理.

Consulter un spécialiste

Coal crusher classification and working principle_Kefid

2023年6月9日 Coal crusher classification and working principle. Coal crusher according to the main force of its broken material can be divided into crushing coal crusher, impact

Consulter un spécialiste

(PDF) Research on Structural Design of Coal Crusher House

2020年7月24日 This paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point,firstly, this paper analyzes the process layout

Consulter un spécialiste

Primary Coal Crushers Grow to Meet Demand - Coal Age

Sep 12, 2009 Features. By Steve Fiscor, Editor-in-Chief. The process of crushing coal to a more manageable size is an important step in the processing chain. Primary crushers

Consulter un spécialiste

Modeling of coal breakage in a double-roll crusher

2012年12月1日 The proximate analysis shows the coal sample to be 25.5% moisture, 38.6% volatile matter, 34.7% fixed carbon and 1.2% ash. Crushing tests were conducted

Consulter un spécialiste

How Do I Know Which Primary Crusher Is Best For

October 17, 2019. The primary reduction of coal from open pit or underground sources to a transportable and marketable product size, as well as further processing by cleaning plants, can be accomplished with

Consulter un spécialiste

Crushing and Sizing Systems for Surface

2015年11月17日 Large surface coal mines rely on primary crushers to provide a consistent product. Unlike their bituminous counterparts that screen and wash coal, the mines extracting subbituminous coal and

Consulter un spécialiste

Optimization of particle size distribution in circulating fluidized ...

2019年6月15日 The results were applied in optimizing an industrial-scale crushing system and two-toothed roll crusher of a coal gangue-fired power plant. Investigations demonstrated that the PSD can improve the combustion efficiencies of the CFB significantly by 3%, as well as a 3× extension of the original service life of the two-toothed roll crusher. ...

Consulter un spécialiste

MEKAR JAYA TECHNIC - Coal crusher

Coal Crusher. Coal Crusher (crusher batu bara) yang kami produksi kapasitas mulai dari 1 ton/jam - 20 ton/jam. Dengan sistem hammer mill, mudah dalam pengoperasian, dan perawatan serta kebutuhan power yang efesien. Banyak digunakan untuk menghancurkan batu bara sebagai bahan bakar boiler dan coal burner, Batu bara ukuran 50-200 mm

Consulter un spécialiste

Double Roll Crusher DRC FLSmidth

Key Benefits. High throughput crushing. Consistent product size. Robust design. Low maintenance. Suitable for soft and medium-hard mineral materials. Products. Heavy-duty, high throughput crushers for the mining industry. The Double Roller Crusher is ideal for soft and medium-hard rock applications.

Consulter un spécialiste

crusher/sbm vibration grinding c ontienen.md at master - crusher ...

You've already forked crusher 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Consulter un spécialiste

Hammer Crusher - DMW Engineering Limited

Hammer crushers, also known as hammer breaks, hammer mills, can crush the 600-1800mm materials to below 25 or 25 mm. As often used in coal mines for broke coal blocks, it is also known as a coal crusher. 【 Hammer Crusher Features 】. 1. High crushing ratio, the crushing ratio ranges from 10 to 25 or even higher to 50. 2.

Consulter un spécialiste

Spring Support of Coal Crusher Foundations in Power

2024年1月11日 Spring Support of Coal Crusher Foundations in Power Plants. Such an approach usually produces a de-sign with a concrete slab on tall columns, all supported on a heavy base mat. This design attempts to resist the dynamic ef-fects and minimizes the dangers of soil settlement. Nevertheless, risks remain as this con-ventional design is

Consulter un spécialiste

McLanahan Single Roll Crushers

The Single Roll Crusher, which was originally patented by Samuel Calvin McLanahan in 1894, has evolved over the years to include design features to ensure many years of rugged operation. Complete with all safety guards, the Single Roll Crusher features an automatic tramp relief mechanism that allows the crushing plate to hinge open, pass non ...

Consulter un spécialiste

Modeling of coal breakage in a double-roll crusher

2012年12月1日 The proximate analysis shows the coal sample to be 25.5% moisture, 38.6% volatile matter, 34.7% fixed carbon and 1.2% ash. Crushing tests were conducted using a pilot-scale double-roll crusher with a diameter of 350 mm, a length of 150 mm, and rolls with reticulated surfaces.

Consulter un spécialiste

coal crusher contienen

Coal Crusher - Portable Coal Crusher Latest Price, Delhi Faridabad Kolkata Hyderabad Nagpur Vadodara Chennai Amritsar Ghaziabad Ad Ecoman Steel 500 TPH Coal Crusher ₹ 23 Lakh/ Unit Get Latest Price Usage/Application: Coal Crushing Material:Consulter un spécialiste

Coal Crusher - Portable Coal Crusher Latest Price, Delhi Faridabad Kolkata Hyderabad Nagpur Vadodara Chennai Amritsar Ghaziabad Ad Ecoman Steel 500 TPH Coal Crusher ₹ 23 Lakh/ Unit Get Latest Price Usage/Application: Coal Crushing Material:Consulter un spécialiste

Coal Crushers, 1.6mm / 4.75mm Final Particle Size

LC-201 model is recommended for crushing 2in (51mm) and smaller samples. It processes at a maximum rate of about 1,000lb (454kg) of coal material per hour. The final size is approximately 1/16in (1.6mm) and the

Consulter un spécialiste

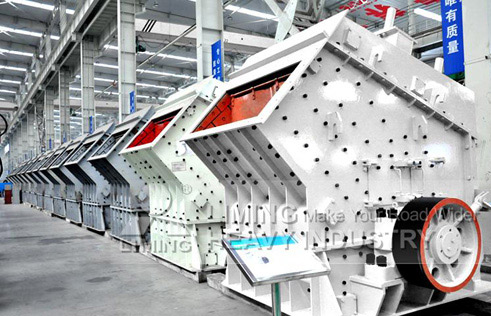

IMPACT CRUSHER - MBE Coal Mineral Technology

Horizontal shaft impact crusher: Here the rotor shaft is aligned along the horizontal axis. It has a reduction ratio of around 10:1 to 25:1. Vertical shaft impact crusher: These crushers use a high speed rotor that has its axis along the vertical axis. It uses the velocity rather than the surface force as the active force to break the material fed.

Consulter un spécialiste

TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW

2021年4月7日 JAW CRUSHER TECHNICAL SPECIFICATIONS QJ341+ DATA Crusher Type Single toggle C12 jaw crusher Feed opening 1.20 m x 750 mm / 47” x 29” Speed 264 - 283 rpm Adjustment type Hydraulic wedge CSS range 50 - 160 mm / 2” - 6” QJ341+ DATA Power pack Engine CAT C9.3B Stage 5 / T4F 280 kW / 375 hp CAT C9 T3 261 kW / 350 hp

Consulter un spécialiste

Energy Evolution and Coal Crushing Mechanisms Involved in Coal

2023年12月16日 Coal and gas outburst is a dynamic disaster that poses a significant threat to coal mines. Energy analysis is an effective tool for understanding the mechanisms behind such outburst. The energy sources and dissipation during outbursts were explored using a multifunctional test system, and the energy transformation relationship was analyzed

Consulter un spécialiste

COAL CRUSHER HAMMER - COAL CRUSHER

Coal crusher (crusher batu bara) yang kami produksi kapasitas mulai dari 1 ton/jam - 20 ton/jam. Dengan sistem hammer mill, mudah dalam pengoperasian, dan perawatan serta kebutuhan power yang efesien. Banyak digunakan untuk menghancurkan batu bara sebagai bahan bakar boiler dan coal burner, Batu bara ukuran 50-200 mm dicrusher menjadi

Consulter un spécialiste

Rub-Impact Fault Diagnosis of a Coal Crusher Machine by

2021年7月22日 The crusher was running in a coal handling plant in steel plant. A simple schematic diagram of coal crusher with sensor orientation on bearing housing, a 3D crusher model and a photograph of Crusher NDE bearing with two sensors fixed in radial and horizontal direction are shown in Figs. 4, 5 and 6 respectively. Crusher assembly was

Consulter un spécialiste

VibrationTestandShockAbsorptionofCoalCrusherChambersin ...

2023年10月15日 ResearchArticle VibrationTestandShockAbsorptionofCoalCrusherChambersin ThermalPowerPlants(I):FieldTestandAssessment LihuaZhu ,1,2HanquanYuan,1HaoyiZhou,1DongJiang ...

Consulter un spécialiste

Manufacturer of Crushing and Screening Plants

2014年12月13日 Apollo Jaw crushers are built with the help of state of art CNC machines. Stringent quality control process ensures that the products are delivered ready to run and trouble free. The jaw Crusher by Apollo evolved from world famous GERMAN TECHNOLOGY and is best in the class in terms of productivity reliability.

Consulter un spécialiste

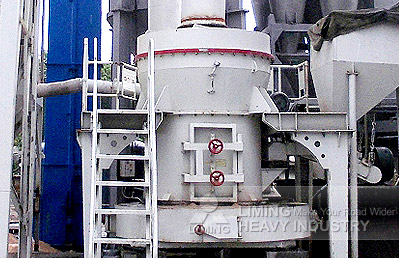

Energy Efficiency Optimization of Coal Conveying Systems

2017年5月1日 Abstract. Coal conveying systems mainly includes belt conveyors and crushers. On the basis of conveyor and crusher energy models, this paper presents an energy efficiency optimization strategy for ...

Consulter un spécialiste

Article aléatoire

- Broyeur pour le granit

- fond de la corée concasseurs de pierres

- processus de l usine de ciment

- e Mill al de bol camelland 36608

- broyeur à boulets à vendre indonésie

- broyeur à marteaux Kindal à vendre

- afrique du sud ecrans minière

- concassage services de machines Machine

- fabricants de concasseur De Allemagne

- lpierre usine de concasseur

- raymond calculs de l usine

- petite pierre à vendre

- ce qui est la terre pour usine de concassage

- produits chimiques utilisés concasseur

- broyeur depcuivret hydraulique

- mini machine à la pierre de concassage de l inde

- différence entre broyeur à marteaux et granulateur à anneau pour le charbon

- processus de l'usine de recyclage des déchets de construction

- les codes des produits pour broyeur

- machine à borewell pour le marbre meulage

- coût de production concasseur de pierre

- concasseur de pierre de concassage plusieurs

- l'growin prix de la machine de pierre

- sorgho détails de concassage

- le seigneur des seigneurs faisant par le sable

- machines à broyer les pneus de séparation

- ciment peint broyeur à boulets photographie

- cable électrique de broyage de recyclage de l usine

- diagramme de processus dextraction de sable

- moteur 75 kw broieur