Requête

Lorsque nous recevrons votre demande, nous vous enverrons par courrier électronique dans les 24 heures les catalogues personnalisés, les tables de prix,

les conditions de livraison, les conditions de paiement et les autres informations nécessaires.

ball mill shell rap motor

BALL MILL DRIVE MOTOR CHOICES - Artec Machine

The mill used for this comparison is a 4.4-meter diameter by 13.6 meter long ball mill with a 5000 HP drive motor. It is designed for approximately 90 s.ton per hour. This type two

Consulter un spécialiste

Charge behaviour and power consumption in ball mills:

2001年8月1日 Ball mills are used in mineral processing for particle size reduction. These consist of a rotating cylindrical shell of up to 7 m in diameter with axial lengths greater

Consulter un spécialiste

Experimental analysis of wet mill load based on vibration

2010年8月1日 After more work on industry scale ball mill is done, the soft-sensor modeling based on the mill shell vibration for operating parameters of mill load will improve the

Consulter un spécialiste

The Ultimate Guide to Ball Mills - Mining-pedia

2019年8月14日 5. The size of the ball mill is large, and it is necessary to carry out lifting work during the process of replacing the ball mill liner. The hoisting ball mill liner is the

Consulter un spécialiste

ball mill size and motor power requirements

2012年12月31日 To match a ball mill size and its motor size, some math is required. The power requirement calculated above is the motor power that must be applied at the mill

Consulter un spécialiste

A Review of Advanced Ball Mill Modelling - J-STAGE

2. Advanced mill modelling prior to DEM. The first attempts in coupling impact energy informa- tion to particle breakage data to predict grinding have been made in the late

Consulter un spécialiste

Ball Mill System – KHD Humboldt Wedag

Extremely compact arrangement. No foundation for the gear reducer. No complicated drive adjustments. The motor can be installed separately from the gears. Does not need to be run in. Low staffing level for operation

Consulter un spécialiste

Modeling Impulsive Ball Mill Forces Effects on the

2022年3月23日 This approach is based on a hybrid numerical model of a 24-degree-of-freedom gearbox, simulating one gear train and two drive shafts. The impact forces of

Consulter un spécialiste

Choosing the Right Motors for your Mills

power Mill Shell Motor Output 0.97 0.96 0.96 1.0 0.985 0.97 CCV/Transformer Input Motor Input 0.98 0.99 0.99 Gearless Synchronous Induction. Step 3: Which Type? ... –Variable

Consulter un spécialiste

Custom Electric Ball Mill Motors Louis Allis

Custom Motor Applications. Fit and Function Replacements. Resources. Specialty three-phase electric motors specifically designed to meet the needs of your application. Low,

Consulter un spécialiste

The Ultimate Guide to Ball Mills - Mining-pedia

2019年8月14日 5. The size of the ball mill is large, and it is necessary to carry out lifting work during the process of replacing the ball mill liner. The hoisting ball mill liner is the responsibility of the hoist. The lifting process requires attention to the operation of the wire rope and the hook. 6.

Consulter un spécialiste

ball mill shell rap motor

sbm ball mill shell rap motor.md main - GitLabSign in / Register Toggle navigation Menu. S shibang ; Project information Project information Activity

sbm ball mill shell rap motor.md main - GitLabSign in / Register Toggle navigation Menu. S shibang ; Project information Project information Activity id/rap shell motor untuk ball mill.md at main luoruoping/idContribute to luoruopi. Accéder au contenu. WhatsApp: +86 187 0363 7156;Consulter un spécialiste

id/rap shell motor untuk ball mill.md at main luoruoping/idContribute to luoruopi. Accéder au contenu. WhatsApp: +86 187 0363 7156;Consulter un spécialiste

Ball Mill - Principle, Construction, Working, and

2024年5月9日 The basic parts of the ball mill are a shell, balls, and motor Fig.2. A ball mill is also known as a pebble mill or tumbling mill. It consists of a hollow cylindrical shell (drum) containing balls mounted on a metallic

Consulter un spécialiste

Rap Shell Motor For Ball Mill - cwr2.arma2

Ball Mill Shell Replacement - YouTube. 18.10.2016 Starting a 6kV 3Ph - 2,200 kW - 1,000 rpm slip-ring motor for a cement ball mill - Duration: 3:51.

Consulter un spécialiste

Orbis Machinery Ball Mills Ball Mill Drive

Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods), the product to be ground is added and ...

Consulter un spécialiste

ball mill shell rap motor - forndelpont.es

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter ( Figure 8.11). The feed can be dry, with less than 3% moisture to minimize ball coating, or

Consulter un spécialiste

Ball Mill - an overview ScienceDirect Topics

8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Consulter un spécialiste

ball mill shell rap motor - lanonnacroissy

2022年12月22日 Ball mill wikipedia a ball mill is a type of grinder used to grind blend and sometimes for mixing of materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the shellball mill shell rap ...

Consulter un spécialiste

ball mill size and motor power requirements

2012年12月31日 The represents a section of a mill in operation. The power input required to maintain this condition is theoretically: hp = (W) (C) (Sin a) (2π) (N) 33.000. where W = weight of charge. C = distance of center of gravity or charge from center of mill in feet. a = dynamic angle of repose of the charge. N = mill speed in rpm.

Consulter un spécialiste

17 Signs of Problems with Ball Mills: Quickly

2023年2月15日 Here we list 17 signs to mention you that the ball mill is running and needs to be checked in. Find the abnormal signs early is very important to prolong the ball mill service life. 1. The sign of "swollen

Consulter un spécialiste

Gearless mill drives - Grinding ABB

Maximum availability and productivity. Go gearless to meet your business objetives by exceeding standard availability targets in your grinding operations. ABB’s GMD is the most powerful mill drive system in the

Consulter un spécialiste

BALL MILL_百度文库

shell, transmission, discharging assembly, coupling, main-motor, lubrication station, hoisting equipment, low-seed drive, electronic control, etc. 2.1.2 Main Structural Features 2.1.2.1 Shell As a main part of ball mill, shell is composed by two ...

Consulter un spécialiste

Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan ...

2022年10月5日 Ball Mill adalah suatu mesin yang berbentuk silinder (tabung) dan berfungsi untuk menggiling material kasar menjadi material yang halus. Mesin ini memanfaatkan bola-bola keras untuk menumbuk dan menggesek material kasar sehingga bisa menjadi halus. Ball Mill menjadi salah satu mesin yang sangat penting dalam proses

Consulter un spécialiste

ball mill shell rap motor

Amazon : Broyeur De Comprimés. TabTime - Broyeur de pilules - Broie plusieurs comprimés en une poudre fine - Idéal pour les tubes d’alimentation, les animaux domestiques ou pour aider les enfants à prendre des

Consulter un spécialiste

Ball Mills – MechProTech

TITAN BALL MILLS. Based on the MPT TITAN™ design, the Mills are girth gear dual pinion driven with self-aligned flanged motors, running on hydrodynamic oil lubricated bearings. The TITAN design enables you to run full process load 40% Ball charge at 80% critical speed – Max grinding power for every shell size. Standard Mill Types Available:

Consulter un spécialiste

Mill drives - INFINITY FOR CEMENT EQUIPMENT

The first finish ball mill driven by a wrap-around motor has been put into operation in 1969 in Le Havre, France. The cement output is rated at 200 MTPH and the motor rating is 8700 HP (metric HP), equal to 6400 kW at 15 RPM. The motor was manufactured by Brown, Boveri and Comp., Baden, Switzerland.

Consulter un spécialiste

Experimental analysis of wet mill load based on vibration

2010年8月1日 The experiments were performed on a laboratory-scale ball mill (XMQL-420 × 450), which is a continuous grinding grid mill.The mill drum is 460 mm in diameter and 460 mm in length, as shown in Fig. 1.The mill, driven by a three-phase 2.12. kW motor, has maximum ball load of 80 kg, a designed pulverizing capacity of 10 kg per hour, a rated

Consulter un spécialiste

The Ball Mill Driving Device Fault and the Main Bearing

2024年3月4日 2074 e-ISSN: 2087-278X TELKOMNIKA Vol. 11, No. 4, April 2013 : 2073 – 2078 The ball mill specifications are : 2.2x6.5meter, Divided into 2 cabins used as the room for feed material mill.

Consulter un spécialiste

What’s the Difference Between SAG Mill and Ball Mill

2019年11月26日 The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 0.1 mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s ...

Consulter un spécialiste

Article aléatoire

- broyage prix d'usine Afrique du Sud a Johannesburg

- ciment broyeurs verticaux à rouleaux par rapport à des broyeurs à boulets

- fabricants de concasseur à aligarh

- mobiles usine de sable de mineraux lourds

- broyeur de vitesse de rotation critique

- machine à laver d&39;occasion à vendre

- appareil pour concasser les amandes

- pièces de concassage 150 tonnes

- la charge de broyage des moulins rotatifs

- sable de silice fabricant de la machine de concassage de carriere

- vis à vis de remplacement pour les distributeurs à vis

- minerai de cuivre et de c blage

- un broyeur a ciment et ensachage de ciment

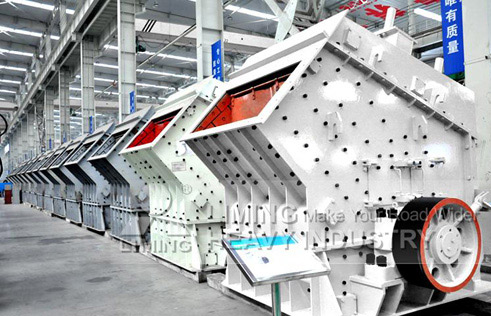

- européen concasseur à percussion

- Cheap processus de polissage de broyage

- broyeurs association corée du sud

- profil de l'entreprise calcaire de la carriere

- SBM concasseur et broyeur

- comment un broyage de minerai de fer et de criblage

- sortie des concasseurs à cône

- comment moudre le cafe dans les industrie

- attaquant concassage et de criblage

- concasseurs de gravier et de lavage de sable

- mesure de broyeur a boulets

- en utilisant léquipement de broyage

- brevetée granulats de construction de la Chine production

- scories de cuivre de laitier de cuivre

- Capacite de 200 tonnes par heure

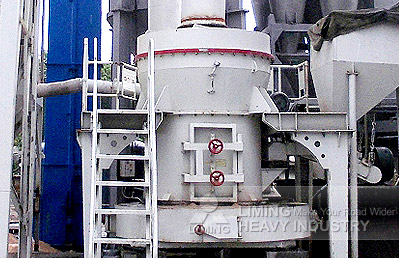

- broyeur usine de pour Calciteerie

- Hilti sans poussière broyeur de béton