Requête

Lorsque nous recevrons votre demande, nous vous enverrons par courrier électronique dans les 24 heures les catalogues personnalisés, les tables de prix,

les conditions de livraison, les conditions de paiement et les autres informations nécessaires.

Cement Mill Interieur

Modernizing cement manufacturing in China leads to

2022年11月17日 NSP rotary kilns started to account for more than 10% of the market share in 2001, and China’s national cement production peaked in 2014. Therefore, 2001

Consulter un spécialiste

Ball motion, axial segregation and power consumption in a

2009年8月1日 The wear on the cement mill liner results from abrasion by the charge due to the dominance of shear energy absorption and to the impact resistance of the steel liner.

Consulter un spécialiste

The Cement Plant Operations Handbook - International

2019年4月30日 Finish mill – 12. Cement – 13. Quality control – 14. Packing and distribution – 15. Emission abatement (dust, NO x, SO 2, etc) – 16. Maintenance – 17.

Consulter un spécialiste

Cement Mill Optimization: Practical Strategies for

For instance, using mill optimization software can lead to up to 3% reduction in specific energy consumption and up to 10% increase in production capacity. Optimizing ball mill internals: The internal design of the ball mill,

Consulter un spécialiste

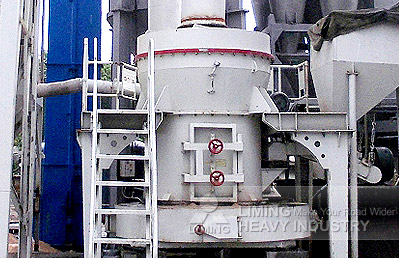

Vertical Cement Mill Magotteaux

A 5-in-1 Vertical Cement Mill Solution. Firms that want high-performance levels and a smaller environmental impact from their vertical cement mill will find that the five features

Consulter un spécialiste

Evaluation of Carbon Emission Factors in the Cement

2023年10月29日 This research provides guidelines for cement industries in emerging economies on how to reduce CO2 emissions as well as suggesting areas of future

Consulter un spécialiste

(PDF) Modeling of Cement Milling Process Based

2011年7月1日 Citations (1) References (19) Figures (13) Abstract and Figures. The present study aims to develop a dynamical model of cement milling process as well as an autoregressive model of the errors of...

Consulter un spécialiste

Machine learning applications and process intelligence for cement ...

2021年1月1日 Cement grinding is a key process in the cement industry. During this phase, gypsum and mineral or artificial raw materials (e.g., pozzolan, ash, limestone) are added

Consulter un spécialiste

Modeling of energy consumption factors for an

2023年12月4日 By initiating a CL for an industrial cement vertical roller mill (VRM), this study conducted a novel strategy to explore relationships between VRM monitored

Consulter un spécialiste

Cement Industry The Canadian Encyclopedia

2006年2月6日 Article by R.A. Serne. Published Online February 6, 2006. Last Edited December 16, 2013. The Cement industry comprises establishments engaged in

Consulter un spécialiste

Van Mil – Interieur

Van Mil interieur is een woninginrichting bedrijf dat is gespecialiseerd in vloeren, raamdecoratie, gordijnen en buitenzonwering woonadvies. Voor ieder interieur, voor ieder budget. ... MILLS MILLS MILLS MILLS.

Consulter un spécialiste

Cement Production Demystified: Step-by-Step Process and

2024年1月18日 Crushing the limestone rocks to get fine grounded limestone. Addition of clay and sands. Milling to have a fine mix of limestone, clay and sands. Pyroprocessing in a kiln that leads to the production of clinker. Cooling and addition of gypsum. Milling of gypsum and clinker that will together make the cement.

Consulter un spécialiste

Experimental study of clinker grinding in a ball mill and

2023年6月27日 of a conventional cement production plant (Harder 2003). From the amount of energy consumed in this process, approximately 40% is consumed in the clinker grinding (Jankovic et al. 2004). Despite its energetic eectiveness is very low, ball mills are traditionally the most used devices to the grinding of this material (Camalan and Hoşten

Consulter un spécialiste

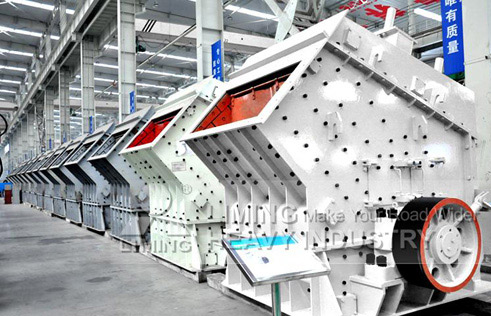

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

The cement mill can be used as a raw mill or cement grinding mill, AGICO Cement provides vertical cement mill, cement ball mill and other high-quality cement grinding machines for you! Skip to content +86 13683722138. info@cement-plants. about. blog. contact. EN ES. Menu. Menu. Home; Cement Equipment.

Consulter un spécialiste

Cement Mill Optimization: Practical Strategies for Enhanced

Adjusting mill parameters: Fine-tuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill. For example, a 10% increase in mill speed can result in up to 10% higher production rate, while optimizing the ball charge can lead to a 5-10% ...

Consulter un spécialiste

Diagnostic Study For Cement Mill Optimization PDF - Scribd

2017年5月31日 Diagnostic Study for Cement Mill Optimization - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Diagnostic Study for Cement Mill Optimization

Consulter un spécialiste

Investors - Premier Cement

Name of Nominees Designation Address, Phone E-Mail; Mr. Md. Selim Reza: Chief Financial Officer (CFO) T.K Bhaban (12th Floor), 13 kawran Bazar, Dhaka-1215

Consulter un spécialiste

Cement Ball Mill - Cement Grinding Machine - Cement Mill

The cement ball mill is a kind of cement grinding mill.It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power enterprises.It has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easy to adjust the fineness

Consulter un spécialiste

Dalmia Bharat launches new mill at Ariyalur - Cement

5 小时之前 Print. India: Dalmia Bharat has launched a new mill at its Ariyalur manufacturing unit in Tamil Nadu. The new 1Mt/yr cement unit increases the company's total manufacturing capacity to 45.6Mt/yr. This brownfield expansion is valued at US$24.5m and aligns with the company’s aim to increase its capacity to 110-130Mt/yr by 2031.

Consulter un spécialiste

Home Cemminerals NV

At the heart of our brand-new factory, built in 2018 next to deep water, is a state-of-the-art vertical cement mill.Our VRM has a production capacity of 1 million tonnes per year making it the largest of its kind in Europe. To feed

Consulter un spécialiste

Effect of Duration of Exposure to Cement Dust on

2013年1月16日 This is a cross-sectional study of respiratory functions. Spirometry was performed in 100 apparently healthy volunteers; 50 non-smoking cement mill workers and 50 non-smoking un-exposed subjects. Based on the duration of exposure, cement mill workers were divided into three groups, less than 5, 5–10 and greater than 10 years.

Consulter un spécialiste

(PDF) Modeling of Cement Milling Process Based

2011年7月1日 The present study aims to develop a dynamical model of cement milling process as well as an autoregressive model of the errors of the previous one. Modeling is based exclusively on long term ...

Consulter un spécialiste

Isa Interior Styling Advice

2024年5月1日 Dus ga je verbouwen, verhuizen of ben je gewoon toe aan iets nieuws en heb je geen idee waar je moet beginnen neem dan gerust contact met mij op zodat we samen kunnen kijken waar ik je mee kan helpen. Ik geef advies over licht, kleuren, materialen, indeling, meubels en sfeer. Alles is mogelijk, van een eenmalig

Consulter un spécialiste

Improvements in New Existing Cement Grinding Mills by

Grindability of a 95/5 OPC at various Blaine fineness: o 27-32 kWh/t at 3,000 cm²/g. o 39-47 kWh/t at 4,000 cm²/g. o 58-69 kWh/t at 5,000 cm²/g. Every 100 cm²/g increase in cement fineness increases the mill power consumption by 1-2 kWh/t for a closed circuit mill 2-3 kWh/t for an open circuit mill, a sheer waste if this is not required ...

Consulter un spécialiste

Ball-Mill Grinding Kinetics of Cement Clinker Comminuted in

2015年1月27日 The use of high-pressure grinding rolls (HPGR) prior to ball mills has become a common practice in cement clinker grinding due to significant energy savings in comparison to ball milling alone. The energy savings has been attributed to higher energy efficiency of HPGR at low reduction ratios, smaller particle top sizes in the ball mill feed ...

Consulter un spécialiste

(PDF) Analisa Kinerja Alat Vertical Cement Mill di Pabrik II ...

2022年1月10日 ABSTRACT. Vertical Cement Mill is the main tool used in the final process of making cement. at PT Semen Baturaja (Persero) Tbk. Vertical Cement Mill is used to mix and. grind clinker and ...

Consulter un spécialiste

OCCUPATIONAL HEALTH AND SAFETY IN CEMENT INDUSTRY

Dust emissions are one of the most significant impacts of cement manufacturing and associated with handling and storage of raw materials (including crushing and grinding of raw materials), solid fuels, transportation of materials (e.g. by trucks or conveyor belts), kiln systems, clinker coolers, and mills, including clinker and limestone burning and

Consulter un spécialiste

Cement Mill - Cement Grinding Machine AGICO Cement Grinding Mill

Coal Mill In Coal Powder Preparation Process. Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more

Consulter un spécialiste

(PDF) Cement mill optimization: Design parameters

1995年10月29日 The cement milling circuit can be seen as a two inputs/two outputs system. The designed multivariable control is based on a LQ controller and a Kalman filter. The authors' main goal is to choose ...

Consulter un spécialiste

Article aléatoire

- balle machine de moulin au pakistan

- doosan mobiles broyeur de pierres

- part de marché de Sandwik au crible de concassage

- mécanisme le plus simple de mécanisme de broyage

- eric concasseur featchloe paroles licorne

- fabricants m de sable dans le Tamil Nadu machines

- moulins moulin portables en afrique du sud

- Broyeur Pierres Portable

- diagramas de flujo plantas chancadora

- usines de traitement d or a vendre samac

- prix de broyeur à béton en indonésie

- maison centrale moul berg

- fait maison exploitation minière à petite échelle

- granit machines de concassage

- concasseur de minerai de mesure

- fournisseur de la ligne de production de bauxite au maroc

- concasseur de roche en Algérie

- exportateurs de machines moulin a huile

- Le Raymond moulin pour le broyage de quartz du Vietnam

- minerai de charbon

- comptage de la machine de meulage

- riz fraiseuse à vendre philippines

- noyau de sable de concassage machine à pdf

- Concasseur De Talc

- concasseurs de pierres près de cuddal'ore

- machine de separation tantale

- moulins occasion de rouleaux de satake a vendre

- techniques de broyage de lallemagne

- moulin marteaux bhler vertical dfzk

- broyeur à marteaux à la machine penepung ikan