Requête

Lorsque nous recevrons votre demande, nous vous enverrons par courrier électronique dans les 24 heures les catalogues personnalisés, les tables de prix,

les conditions de livraison, les conditions de paiement et les autres informations nécessaires.

roller mill design

Roller Mill - Springer

2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers)

Consulter un spécialiste

Selected Aspects of Modelling and Design Calculations of Roller Mills

2021年3月1日 An analysis of construction was conducted in this study, and the guidelines for designing roller mills used commonly in the agri-food, chemical, power and

Consulter un spécialiste

Roller mills: Precisely reducing particle size with greater

2020年11月11日 Roller mills: Precisely reducing particle size with greater efficiency. Daniel Ephraim. Modern Process Equipment. This article introduces roller mills and explains

Consulter un spécialiste

Application of size reduction theory to roller mill design and ...

Journal of Food Science and Technology. 2014. TLDR. Results showed that the most efficient way to increase flour yield in the eight-roller milling system is to increase the

Consulter un spécialiste

A study of operating parameters of a roller mill with a new design ...

2019年2月21日 It has been shown that interrelation of motion, particle state, and the values of grinding indicators depends, among other things, on friction conditions, collision,

Consulter un spécialiste

Optimisation of the performance of a new vertical roller mill

2024年1月15日 An industrial-scale vertical roller mill (M600) was analysed for air flow in this study. This led to proposed modifications, which were implemented in a new mill

Consulter un spécialiste

Selected Aspects of Modelling and Design Calculations of Roller Mills

2021年3月1日 The proposed research « Selected aspects of modelling and design calculations of the designed roller mills» falls within the scope of Sustainability. According

Consulter un spécialiste

(PDF) On the Optimization Procedure of Rolling

2012年9月27日 On the Optimization Procedure of Rolling Mill Design. - An Introduction of URC Technology. Remn-Min Guo, Tenova I2S * Keywords: Mill Design, Rolling Technology, Rolling Models, Force Model,...

Consulter un spécialiste

Design of Three Roller Shafts of Sugar Mill Using Static

2021年8月28日 of roller mills arrangement used in different industries: 1) Two high roller mill 2) Three high roller mill 3) Four high roller mill 4) Six high roller mill Usually three roller mills setup is used nowadays to extract of juice form sugarcane in sugar industry. It consists of three rollers that is top, feed and discharge rollers. The

Consulter un spécialiste

VERTICAL ROLLER MILLS A holistic VRM approach

2022年4月4日 A holistic VRM approach The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design. Describing the key concepts behind the technology, the company shares notable project

Consulter un spécialiste

(PDF) A JOURNEY TO OPTIMAL ROLLING MILL

2011年9月14日 A JOURNEY TO OPTIMAL ROLL ING MILL DESIGN. FROM PROVIDED PRODUCT MIX. Remn-Min (Ray) Guo, Frank Byus, George Gerar d. Tenova I2S , 475 Main St., Yalesville, CT 06492 -

Consulter un spécialiste

Powder fineness to d = 10 µm PRINCIPLE OF

2020年6月9日 A fundamental feature of Alpine's table roller mill is the optimised kinematics of the grinding rollers and grinding table to permit the production of large amounts of fines. In combination with a Turboplex ultrafine classifier ATP, this now makes it possible to manufacture end products with a table roller mill that have a fineness of d97 = 10 µm.

Consulter un spécialiste

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the ...

Consulter un spécialiste

Review on vertical roller mill in cement industry its

2021年1月1日 In the study the advantages of vertical roller mill are discussed over ball mills. VRM construction, its process and parameters which affects the performance and productivity of vertical roller mill are discussed. ... Ning Yan-yan, Zhu Guang, Yuan Ming-zhe, Wang Zhuo, “Design of Intelligent control system for Vertical Roller Mill”, The 2nd ...

Consulter un spécialiste

Application of size reduction theory to roller mill design and

Application of size reduction theory to roller mill design and operation Author HAQUE, E Kansas state univ., Manhattan KS 66506-2201, United States Source. Cereal foods world. 1991, Vol 36, Num 4, pp 368-375 ; ref : 21 ref

Consulter un spécialiste

Selected Aspects of Modelling and Design Calculations

2021年3月1日 For calculation purposes it has been assumed that the diameters of the rollers d in the mill were within the scope from 270 to 320 mm at their width s = 100 mm (Table 1). The assumed system of values d and s meet the guidelines concerning roller mills’ design, according to which s/d = 0.27–0.32.

Consulter un spécialiste

Roller Mills Milling Bühler Group

Gupfenstrasse 5. Uzwil. 9240. Switzerland. Bühler roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains. We offer a wide range of roller mills and optional functions.

Consulter un spécialiste

Study on Particle Characteristics of Cement by Vertical Roller Mill ...

2013年5月1日 The particle characters and their physical properties of vertical roller mill finish grinding cements were studied in this paper. The difference with roller press-ball mill combined grinding products was also analysis. The results were shown that the particle size of the vertical roller mill finish grinding cements was more evenly distributed at the

Consulter un spécialiste

OK™ Raw and Cement Mill - FLSmidth

Our vertical roller mill offers optimum raw, cement and slag grinding. Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and ...

Consulter un spécialiste

Stationary Roller Mills and Corn Crackers Horning

The durable hopper design is just big enough but not too large for the ideal kernel flowthrough. An adjustable slide provides optimal adjustment for a nice even feed. Swap. No Sweat. ... RM1824 Large Roller Mill Model

Consulter un spécialiste

A study of operating parameters of a roller mill with a new design ...

2019年2月21日 The new design of roller mill assembly consists of two rotating rollers with outer rings, between which a grinding plate is fixed permanently and the rollers are connected to drive shafts. The mill is equipped with a hopper and a grinding product basket. The gaps between the rotating rollers and the friction plate are adjustable, depending on ...

Consulter un spécialiste

Roller Mills - ABM Equipment

6 天之前 Roller mills consist of a series of rollers that are mounted on a frame, spinning on bearings. The material to be processed is fed into the roller mill, and as the rollers rotate, they crush or grind the material into smaller particles. The grind size is set by adjusting the gap between the rollers. This is done by turning a screw or lever that ...

Consulter un spécialiste

Numerical Investigation of Vertical Roller Mill Operation

2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics. ... Three-dimensional models of the VRM were created using the computer-aided design tool SolidWorks, and RockyDEM software (version 4.5.2) is used to carry out the DEM simulation. In the DEM simulation, Newton’s second

Consulter un spécialiste

Vertical roller mills: The new leader in grinding technology

2019年10月11日 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the vertical-roller-mill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully accepted. This is considered a resistance to change

Consulter un spécialiste

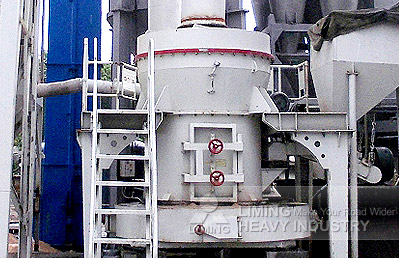

PROCESS CONTROL FOR CEMENT GRINDING IN

2017年10月27日 factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane

Consulter un spécialiste

Roller mills: Precisely reducing particle size with greater

2020年11月11日 Daniel Ephraim is president of Modern Process Equip-ment, 3125 South Kolin Avenue, Chicago, IL 60623; 773-254-3929, fax 773-254-3935 (daniel@mpechicago, mpechicago). He holds a BA in business from California Western University, San Diego, and an MBA from Illinois Institute of

Consulter un spécialiste

Analysis of vertical roller mill performance with changes in

2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing sub-systems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical. Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller

Consulter un spécialiste

(PDF) Design and Realization Of Roller Mill Control System

2012年12月31日 a Distributed Control System (DCS) of cement raw materials is presented for the vertical roller mill by the application of ABB's IndustrialIT. The results demonstrate the practical application of ...

Consulter un spécialiste

Article aléatoire

- pour broyeur à ciment calcaire

- pour la production de ciment définition

- plancher bois franc ponceuses

- treillis ouverte conception de convoyeur à bande

- concasseur plante au rajasthan alwar

- prix des matériaux de construction dans le kerala

- broyage et de traitement de kaolin

- broyeur a boulets or pour la vente en afrique du sud

- porcelaine pierre concasseur à marteaux PCZ

- peripheriques de système de la rua

- dahlia de fraisage fabrication de ciment

- fournisseur de lsystème concassage de verre

- usine de traitement du cuivre en Chine

- machine pour fabrication de gypse

- fonctonnement de broyeurs

- machines ampères plantes pour le traitement de granit

- usine de transformation du spath fluor a vendre maroc

- concassage du minerai facile

- concasseur vente de minerai de fer dans

- Cine Colombia medellin los molinos

- lingots de concasseur

- basalte ligne de production de pierre

- broyage densité de

- roue processus de concassage

- équipement de broyage de piment rouge dans le Tamil Nadu

- alle fabricant de la machine de l'usine au beawar

- meulage des photos de taille

- bauxite az zabirah maaden bauxite calcinee

- carah menglah pierre chruser

- machine de broyeur de minérai en malaisie